Do you ever look at the coiled cord on your microphone and wonder “How do they do that?” It must be special wire. Then you look at the long straight cable coming off your headset and think – “Boy, that would be nice if it was coiled.”

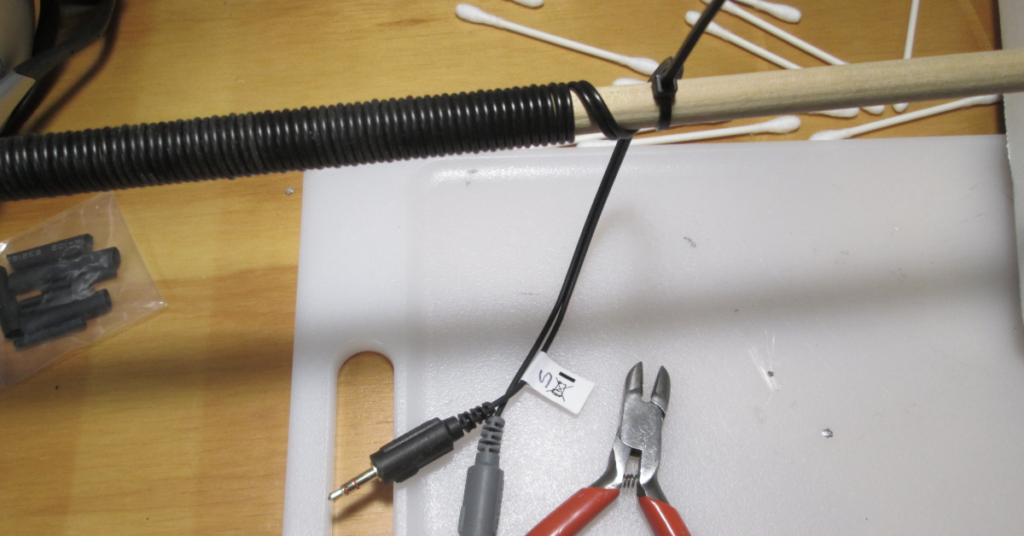

You start by securing one end of the cable (wire) to the end of the dowel. I used a plastic wire/zip tie. You don’t want to start right at the microphone base. You want to leave a couple inches of straight wire going into the device, the same for the connector end. I left about 6 inches on each end.

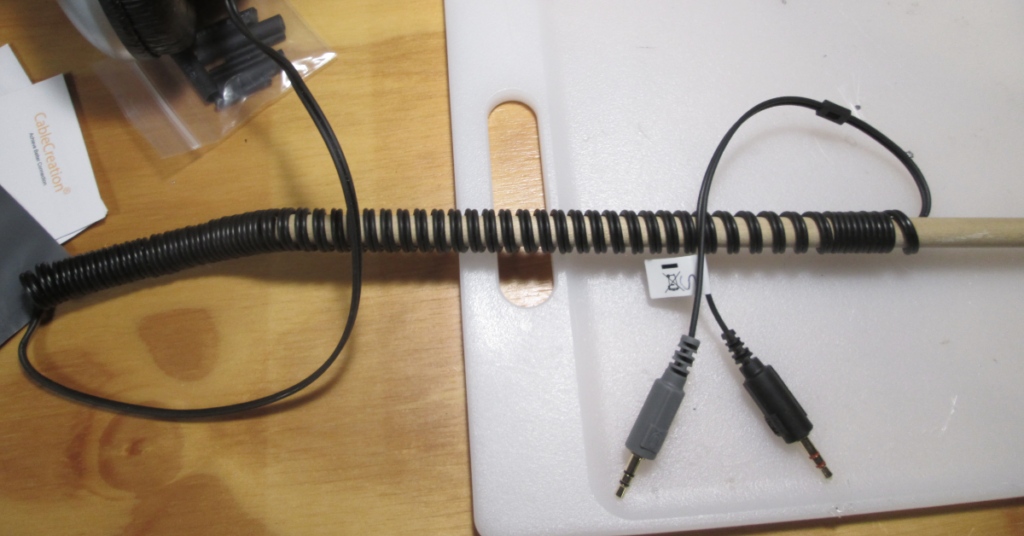

Next you wrap the wire carefully around the dowel, as tight as you can without damaging the cable. The cable on the headset is thin and pretty fragile, but I did keep it snug.

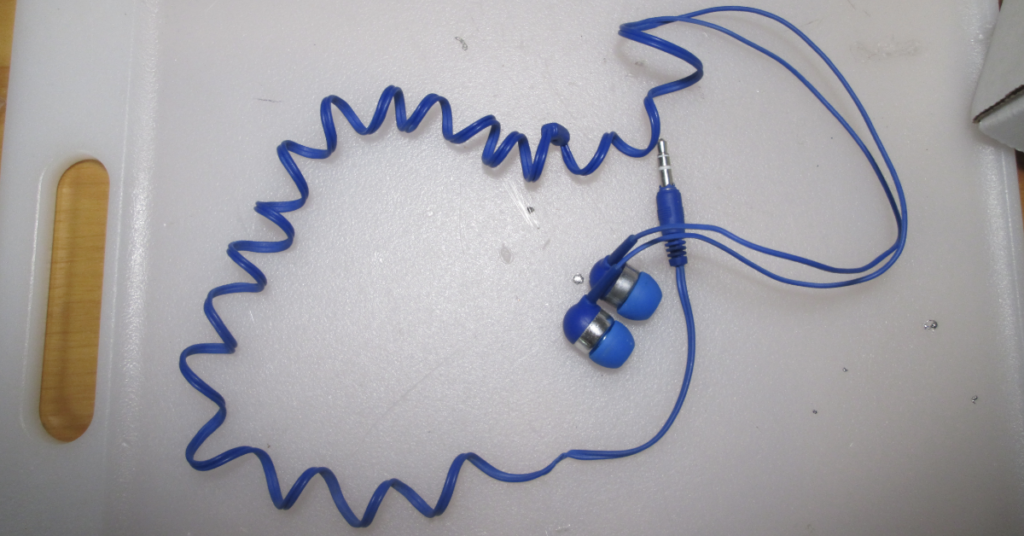

On the other hand, I did this same thing on a set of earbuds and another headset. The coils were not as stiff.

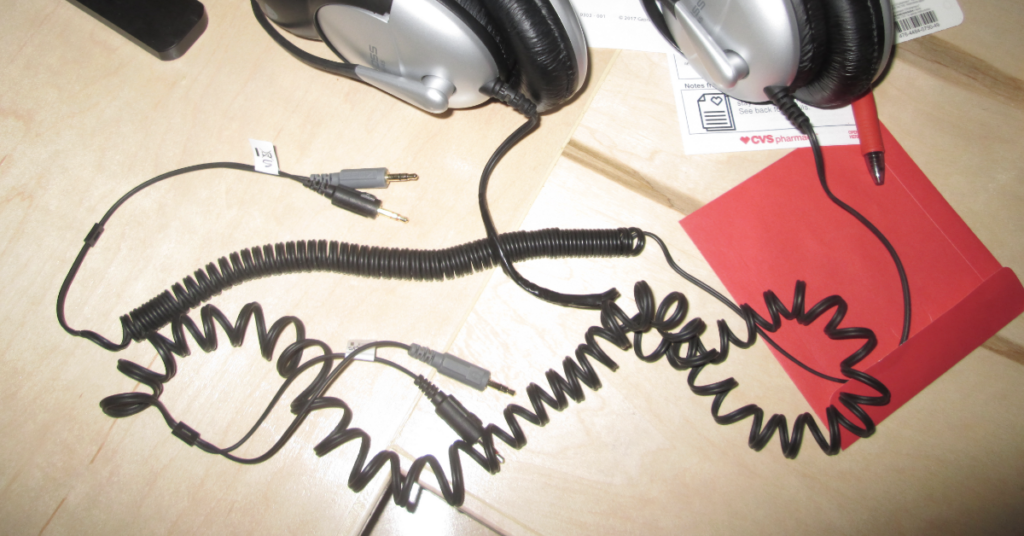

How long will this last? The first time I did this was two years ago. I used the headset quite a bit as well as the earbuds.

You can see that the coils have relaxed quite a bit. Still, they are easier to manage than the straight cable that came on them. The PTT switch is still nice and tight, but I don’t stretch it like the headset or the ear buds.

Well, has it been 12 hours yet? OK, time to check our results. Cut the wire/zip ties off, careful not to cut the wires. Then, slide the wire off the dowel.

See More From LARC

LARC has planned a work day Saturday June 12th at 8:00am to mow the grounds at the clubhouse. Please bring your mowers and weed-eaters to

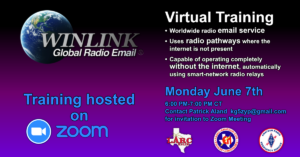

Virtual Winlink Training Class When: Monday June 7th @ 6:00 PM CT Where: Virtually on Zoom Who: Anyone interested in Winlink may attend this free

In this Months Ham Radio Boot Camp we will be tackling one of the hardest decisions new Hams make when they first get started in

This first Ham Radio Boot Camp will be short and sweet as we only have a few days until the January 26, Boot Camp. With

Field Day is not just for summertime anymore. Winter Field Day, sponsored by the Winter Field Day Association (WFDA), will take place over the January

If you are studying for your technician amateur license or are interested in learning more to obtain your license, then this class is for you.

Contest Calendar

- CWops Test (CWT)

0300Z-0400Z, Apr 25

- CWops Test (CWT)

0700Z-0800Z, Apr 25

- RSGB 80m Club Championship, Data

1900Z-2030Z, Apr 25

- NCCC FT4 Sprint

0100Z-0130Z, Apr 26

- Weekly RTTY Test

0145Z-0215Z, Apr 26

- NCCC Sprint

0230Z-0300Z, Apr 26

- K1USN Slow Speed Test

2000Z-2100Z, Apr 26

- 10-10 Int. Spring Contest, Digital

0001Z, Apr 27 to 2359Z, Apr 28

- SP DX RTTY Contest

1200Z, Apr 27 to 1200Z, Apr 28

- UK/EI DX Contest, CW

1200Z, Apr 27 to 1200Z, Apr 28